Armor Non-Slip Additive

Pairs well with

In stock! Ships same-day when placed M-F before 3 PM EST.

Need support? Contat us at 866-306-0246.

Armor Non-Slip Additive

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

Helps To Increase Surface Traction

The Armor Non-Slip Additive is designed to help increase surface traction and reduce surface slipperiness when wet.

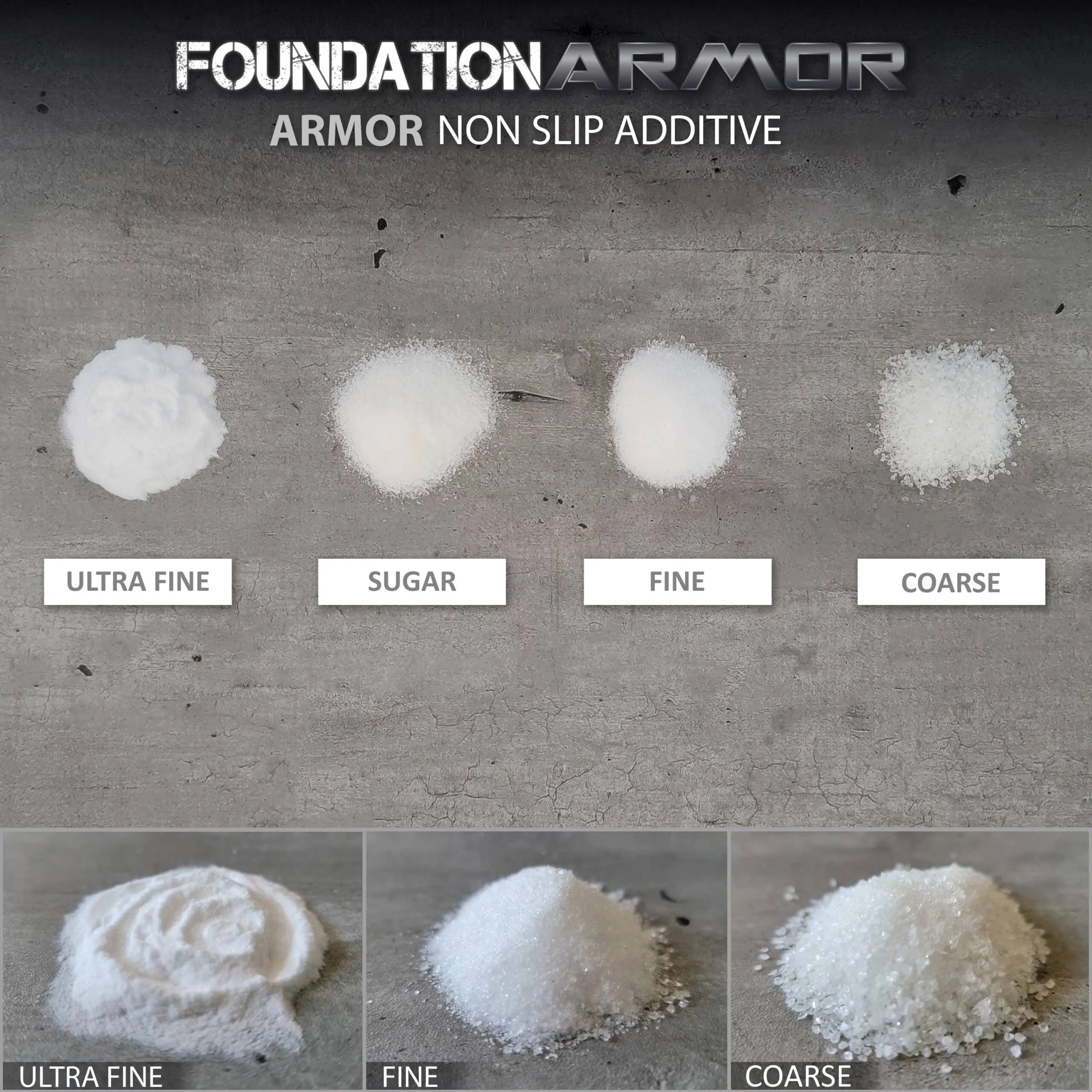

It is available in ultra-fine, fine, and coarse grits and can easily be applied directly into the topcoat of the acrylic sealer.

Helps To Reduce Slipperiness When Wet

If you are concerned about the surface being slippery when wet, the Armor Non-Slip Additive is a great choice! The polymer additives help to increase surface traction and reduce slipperiness caused by having a wet surface.

Free shipping and returns

Product details

Application

(1) 16 Ounce Armor Non-Slip additive container can be used for up to 5 gallons of sealer.

Acrylic Sealer Application: For water and solvent based acrylic sealers, like the Armor AR350, Armor AR500, Armor AX25, Armor LV15, Armor LV25, Armor WB25, and Armor WB15, mix approximately 3-6.5 ounces of Armor Non-Slip Additive per gallon of sealer. Non-slip additive should be applied with the second coat. Applying the Ultra-Fine: Slowly drill mix non-slip additive into the coating until completely blended, then apply. For Fine and Coarse: When applying the second coat, add the non-slip additive to the coating using a broadcast spreader, and back roll to encapsulate the non-slip additive.

Penetrating Sealer Application: Do not use with penetrating sealers such as the Armor SX5000 WB, Armor SX5000, Armor WL550, Armor S2000, or Armor L3000. Non-slip additives should not be used in penetrating silane-siloxane sealers, silicate sealers, or siliconate sealers because these types of sealers work entirely below the surface and do not leave a film or coating.

Coverage

(1) container of non-slip is 16 OZ, which is enough for up to 5 gallons of sealer.

FAQs

Can I mix into a penetrating sealer?

No, the Armor Non-Slip additive can't be applied to penetrating sealers like the Armor SX5000 and Armor WL550. The Armor Non-Slip additive is a solid material and needs to be suspended into a coating in order to function.

Can I add it into a sprayer before applying?

No. Sprayers are designed specifically for liquids, and the Armor Non-Slip additive is a solid. It must be applied as directed.

Will it make the surface completely slip free?

The Armor Non-Slip Additive is designed to increase the surface traction of the concrete. While it can help quite a bit, it can't make the surface 100% slip free when wet. How much surface traction the additive adds will depend on the grit of the non-slip, the amount applied, the coating, and the surface.

How do I know which grit to use?

The Fine grit is the most popular, but ultra-fine and coarse are also great options. Typically, the ultra-fine is used in applications where slipperiness isn't a huge concern but some protection is wanted, and coarse is used in applications where slipperiness is a big concern and the most protection is wanted.

What if I already have a coating down and want to add it?

If you already have a coating down and want to add the non-slip additive, you will have to apply another coat with the non-slip additive applied with it.